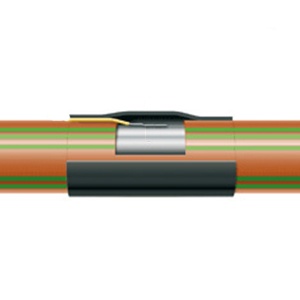

PE 100-RC pipe with added protective layer made from polyethylene PEplus and electrically conductive interim layer for permanent leak detection.

The egeplast 3L Leak Control offers the possibility of permanent leak detection and localisation of damage accurate to the metre. It is the only PE pipe system to meet the requirement of continuous leak detection in accordance with ATV-DVWK-A 142 in the case of very high hazard potential.

The pipe system can be used both for pressure pipelines and gravity pipelines. It can be used wherever safety is the most important factor! Wastewater pipelines which run through water protection zones for example, drinking water pipelines, but also industrial pipelines conveying sensitive or critical media can be monitored easily using this system.

The run of pipe to be monitored is connected by means of an adapter via cable to a monitoring unit. It is then possible to apply a measurement voltage to the detection layer integrated in the pipe. This is a low voltage which is harmless for man and nature. In the event of damage to the pipe, the detection layer comes into electrical contact with the surrounding soil, triggering a pulse in the monitoring device. The damage can be signalled using acoustic signals, by light signal or by transmission to a mobile phone or a control centre.

One method of locating damage in the case of non-sealed surfaces is using ground spikes. The ground spikes are positioned in the surface of the ground above the pipe. Any damage that arises can be measured to the metre by measuring the potential resistance.

If a surface is sealed after installation of the egeplast 3L Leak Control pipe, measurement using ground spikes is only possible to a limited extent. In these applications, the client lays a measuring cable with measuring sensors parallel to the pipeline. The location of the damage can be measured using this. This minimises the time and costs involved in breaking up the surface.